PROJECT REPORT FOR 2000BROILER POULTRY

(ALL IN ALL OUT SYSTEM)

This Project report 2,000 broiler poultry has been worked out subject to the following conditions:

- Hybrid Broiler Chicks will be purchased from commercial hatcheries for every batch.

- Sale price of finisher birds will change in accordance with change in purchase price of feed & chick .

- .Bio-security measures must be strictly adopted.

- The farm must be managed by the entrepreneur on scientific lines.

- Cost of labour has not been taken into consideration since full time labour is not required for the small unit. Family labour will be utilized for maintenance of the farm

- The scheme is a broad guideline and is likely to vary as per the change in price/cost of various specified items

Farmer must check the following points before starting a Broiler farm.

- Availability of hybrid broiler chicks in local market

- Nearness of the Farm to Veterinary Hospital, Animal disease diagnostic laboratory

- Marketing facility & demand of Broiler in local market

- Availability of broiler feed & medicine in their locality.

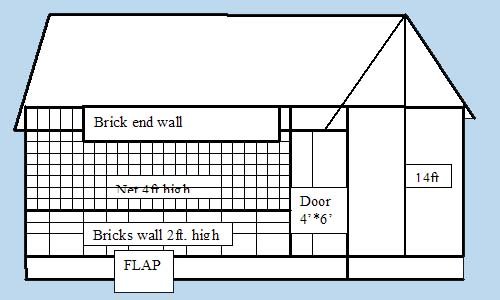

Housing for broiler chicken

Floor – One square feet floor space per bird is required for broiler chicken. The floor of the poultry house should be concrete cemented, strong & rodent proof ,and have slope towards door. Plinth should be 2ft. higher than ground.

Walls-lengthwise wall may be only one foot high, brick wall on sides,4ft wire netting above brick wall should be supported with angle iron. End wall of poultry house should be made of bricks. Maximum breadth of poultry house should be 27 feet. There should be partition in every 500 squire feet.

Roof – Roof of the poultry house may be of asbestos or tile. Low cost roofing material can be used to reduced cost of construction. It should 12-ft. high at the center and 6-8ft. high on the side wall with 3ft extension of roof beyond wall to prevent rain water from entering poultry house.

| Techno-Economic Norms | |

| PARAMETERS | VALUE |

| System of rearing | Deep Litter system |

| Batch size | +5% extra |

| Batch interval | 52 days(45 days r +7days (cleaning ) |

| Mortality of birds | 5% |

| Cycle size | 2000 |

| Cost of day old chick | Rs.33 |

| Cost of kg of feed | Rs.39.00 |

| Cost of equipments( waterers feeders etc.) | Rs.30/bird |

| Cost of insurance medicine vaccine etc. | Rs.6/bird/year |

| Insurance per bird | 0.5 |

| Insurance of building and equipment | 0.001 |

| No of batches/year introduced first year | 6 |

| No of batches /year(sold) | 6 |

| No of batch introduced 2-5 years | 7 |

| No of batch sold 2-6 years | 7 |

| Cost of kg of live broiler | Rs.101 |

| Feed conversion ratio FCR | 1.6 |

| Average wt. of bird at the time of sale | 2kg |

| Feed requirement to attain 1.8kg body weight | 3.2kg |

| Rearing period | 45 days |

| Cleaning period | One week |

| Interest rate | 12%/year |

| Repayment period | 6 years |

|

ECONOMICS OF BROILER FARMING TO PRODUCE 2000 HYBRID BROILERS PER CYCLE UNDER |

||

| Sl no | Capital cost | (Amount in Rs.) |

|

|

Construction of Brooder cum grower house one sq.ft/bird for 2000 birds @Rs.250/sq.ft | 500000 |

|

|

Equipments for 2000 birds @Rs.30/bird | 60000 |

|

|

Electrification & electrical installation | 20000 |

| TOTAL CAPITAL COST | 580000 | |

| Working Capital | ||

|

|

Cost of chicks 2060 chicks @ RS.33chick (5% extra for mortality 2% free fro hatchery ) | 67980 |

|

|

Cost of concentrate feed@3.2kg/bird for 2000 birds @39/kg for first batch | 249600 |

|

|

Misc, expenditure i.e. electricity vaccine medicine insurance etc. including veterinary aid @Rs,6/bird/batch for first batch | 12000 |

|

|

Contingency | 10420 |

|

|

Total working capital | 340000 |

|

|

Total project cost | 920000 |

|

|

Margin money 15% of project cost | 138000 |

|

|

Bank loan | 782000 |